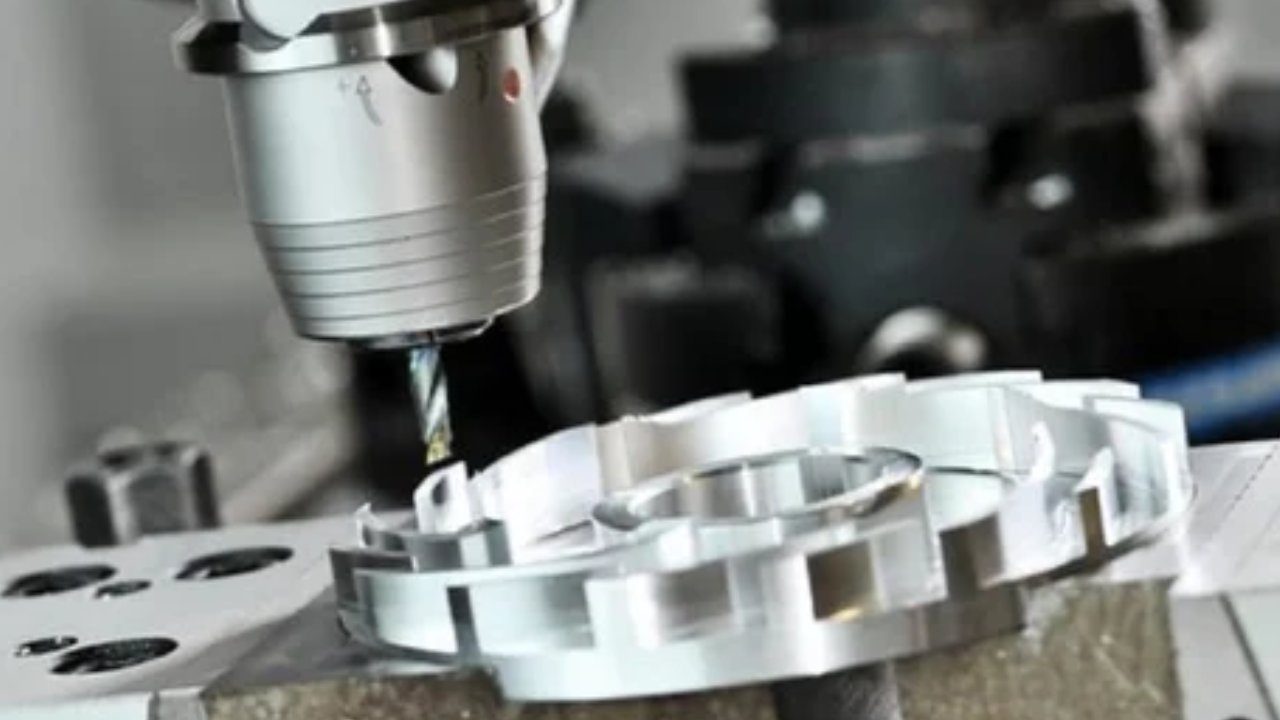

What Rewards Do CNC Machining Over Hand Tools Have?

CNC machining, also known as computer numerical control machining, is a very sophisticated manufacturing technique that uses computer systems to regulate the motion and function of machine tools. By replacing conventional hand machining techniques, this technology enables accurate and automated part and component manufacture.

The cutting tools are guided with remarkable accuracy by CNC machines, which translate design specifications from computer-aided design (CAD) files into numerical code. Metals, polymers, and composites are among the materials that can be processed with this technique.

The production of complex and sophisticated geometries with CNC machining is well known for guaranteeing consistency, repeatability, and high-quality results. Visit Here to learn more about CNC machining. It contributes to creative and effective production processes and is widely employed in a variety of industries, including electronics, automotive, aerospace, and medicine.

Rewards CNC Machining Have Over Manual Machining

We will discover the several advantages that CNC machining holds over manual machining, highlighting the effect it has on productiveness, accuracy, and the overall evolution of the manufacturing panorama.

Precision and Accuracy

One of the number one blessings of CNC machining is the unparalleled precision it gives. CNC machines function with terrific accuracy, pushed by PC-managed systems that do away with the range related to human intervention in guide machining. The removal of manual mistakes guarantees that every component produced through CNC machining adheres exactly to the desired layout, resulting in superb, steady parts.

Complicated Geometries and Complex Designs

CNC machining excels at producing complex and complex designs that could be challenging or impossible to attain manually. The ability to precisely control the motion of reducing equipment in more than one axe allows for the creation of highly unique and sophisticated components. This capability is in particular valuable in industries along with aerospace, automotive, and medical, where complicated components are often vital to the general capability of the very last product.

Repeatability and Consistency

CNC machining ensures a high level of repeatability within the manufacturing method. Once the software is advanced and examined, the CNC machine can reflect the same procedure continuously, generating identical parts with minimum version. This repeatability is essential for large-scale production runs, where preserving consistency throughout several components is important for the assembly of exceptional requirements and specifications.

Decreased Human Mistakes

Guide machining is inherently liable to human blunders that may result in variations in dimensions, surface finishes, and average component. CNC machining significantly reduces the chance of errors due to fatigue, miscalculations, or lapses in awareness. The automatic nature of CNC machines gets rid of the want for steady human supervision, resulting in a more dependable and error-free manufacturing process.

Enhanced Productivity

When compared to hand milling, CNC machining significantly increases productivity. CNC machines maximize manufacturing efficiency by operating constantly and leaving them unattended for lengthy periods. Tool changes, part loading, and unloading procedures can be automated to reduce downtime between operations, which accelerates cycle times and boosts throughput. Meeting strict manufacturing deadlines and cutting lead times are made possible by this increased productivity.

Versatility and Flexibility

CNC machining provides unmatched versatility in meeting a range of manufacturing needs. It is possible to program the same CNC machine to create different components just by altering the computer software’s design criteria. Without requiring significant retooling or reprogramming, this adaptability enables producers to react swiftly to design changes, modify goods, and adjust to changing market demands.

Optimized Material Usage

CNC machining makes it possible to use materials more effectively while decreasing waste and cutting manufacturing costs all around. Because of their precision, CNC machines can cut materials with very small margins and optimize part layouts on raw material stock. The optimization process not only preserves resources but also lowers expenses, rendering CNC machining a financially and environmentally sound option.

Improved Safety Measures

When compared to hand milling, CNC machining fosters a safer working environment. Operators no longer need to be in close contact with moving parts and cutting instruments thanks to the automation of cutting processes. This makes the workplace safer for those who work in manufacturing by reducing the possibility of mishaps and injuries related to manual machining procedures.

Conclusion

With many advantages over manual machining techniques, computer numerical control (CNC) machining is evolving the manufacturing business. Complex and superior component production has never been possible before thanks to CNC machines’ accuracy, effectiveness, and adaptability. The future of manufacturing is being shaped by innovation and the need for efficiency and precision, and CNC machining is still a key component in this regard.

Benedict

Benedict loves to travel. He has explored many different cultures, and he loves to try new foods. His favorite pastime is exploring new places, and He always looks forward to his next trip.